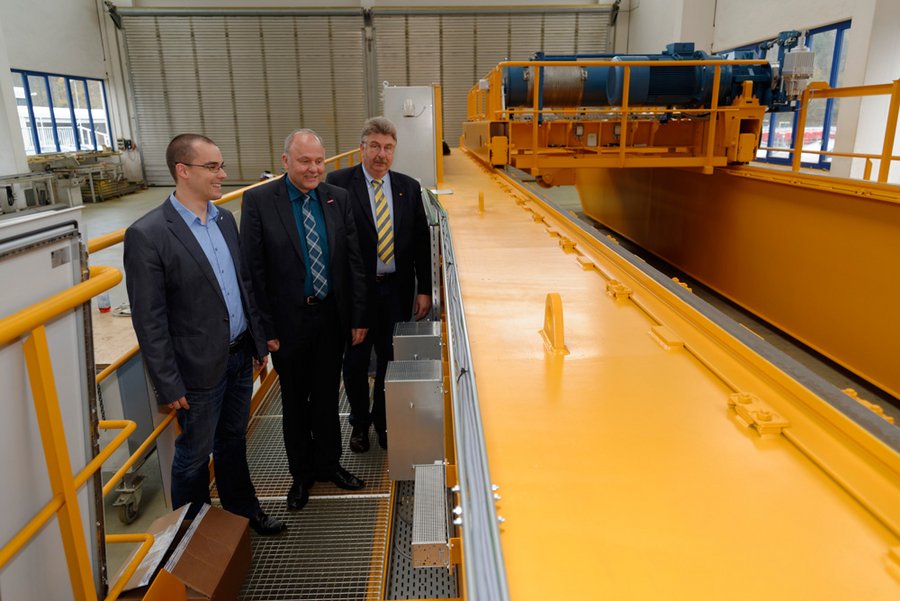

The board of the Siegen Electrical Guild was impressed by the huge crane systems being built at Erich Schäfer GmbH & Co. KG in Siegen-Feuersbach. Before their meeting, the members were given a tour of the factory, construction department and warehouse.

What began over 60 years ago as a small one-man company in the somewhat remote Siegen district now enjoys an excellent international reputation in drive and conveyor technology and has developed into a leading supplier in this particular market segment. “We all pull together,” says Stephan Skelo. The graduate engineer explained to the group the steady development of the company, which now employs 150 people.

Many customers require individual solutions. Erich Schäfer GmbH & Co. KG specializes in. For example, there is the mighty foundry crane that the company designed and built on behalf of a foundry for large rollers: the giant can also transport very large rollers weighing up to 170 tons each.

The Feuersbacher design engineers respond to the special requirements of their customers. In foundries, for example, this means adapting to the direct current technology that is often still used there and to the particularly harsh operating conditions characterized by high temperatures and foundry dust. The intelligent control technology must be specially protected and cooled. Skelo: “If a customer has special requests, we fulfill them.” From the first customer meeting to design, production and commissioning, all steps are in the hands of Erich Schäfer GmbH & Co. KG. The specialists can also react quickly and flexibly with their second mainstay, trading in standard motors. “We always have 6000 motors (IE 1 to IE 3) in stock here,” says Skelo. For practically all required sizes and brands, all you need to do is reach into the modern high-bay warehouse. “Our customers value the fact that we can carry out repairs as quickly as possible.”

No wonder, because in industry, downtimes of such important transport and conveyor systems can quickly cost large sums of money. In this respect, the assembly and maintenance of crane systems is also a fundamental part of our range of services, says Skelo. The company is also exemplary when it comes to training. There are two apprentices in the commercial area and usually two to five in operations. Stephan Skelo: “We like to take on our apprentices because they are already very familiar with our particular circumstances and requirements and therefore don't find it as difficult as outsiders.” Because the company has always placed great importance on a good working atmosphere, there are quite a few employees who have remained loyal to “their” Erich Schäfer GmbH & Co. KG for their entire working lives. In addition to the high level of expertise and reliability, this is probably another key to success: “Many of those who have worked here from the very beginning have a special connection to the company.” KPE