For more than 130 years, Kind & Co., Edelstahlwerk, GmbH & Co. KG has been producing high-quality tool steel in Germany for 130 years. In future, the company will be supported by an automatic crane from Erich Schäfer. This was integrated into an existing finished parts warehouse and is intended for the transportation of very heavy loads. The project was a particular challenge because, in addition to the development and implementation of the new automatic crane in the customer's finished parts warehouse, the entire safety concept also had to be redesigned by Erich Schäfer.

The demand for the highest possible quality is always a priority for Kind & Co. In order to meet this requirement of its customers as usual, Kind & Co. Erich Schäfer to realize an automatic crane for use within a finished parts warehouse at its traditional Wiehl/Bielstein site. Erich Schäfer was able to implement the project in the shortest possible time in accordance with the current state of the art and in compliance with recognized safety regulations.

Automatic crane for finished parts warehouse:

- Up to 18,000 kg load capacity

- Automatic storage and retrieval of round bars and flat steel up to 6 m long

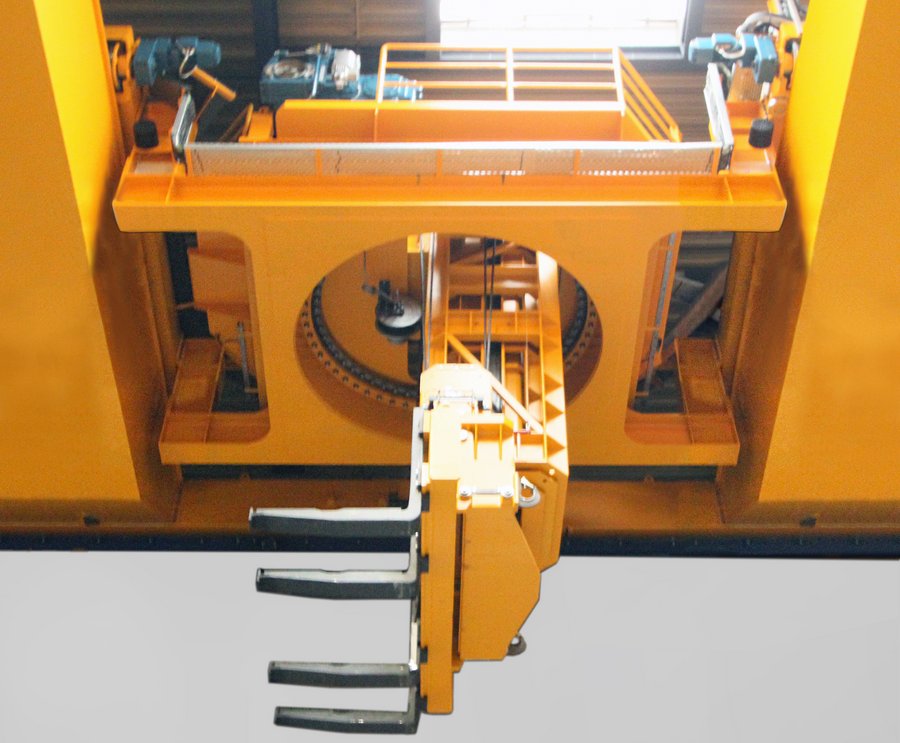

- Trolley with winch, telescope and slewing gear

- Automatic, manual and emergency operation

- Optional radio control

Interaction with provided machines

“In addition to the automatic crane, the entire safety concept for the finished parts warehouse had to be planned and implemented by Erich Schäfer, taking into account the loading and unloading machines we provided, such as a manual crane. Due to the limited space available, it was a challenge to develop a safe and practicable solution for the accessibility of the automatic crane,” explains Dipl.-Ing. Rainer Morgenroth, Head of Production & Process Technology at Kind & Co. But thanks to Erich Schäfer's solution-oriented approach and technical expertise, the challenge was successfully mastered, continues Mr. Morgenroth. Thanks to the new automatic crane from Erich Schäfer, loads of up to 18 tons can now be transported in the converted Kind & Co. finished parts warehouse in conjunction with the machines provided by Kind & Co. First, the loads are removed from the industrial truck using the manual crane and placed in the storage position. After a few intermediate steps, such as activating a light grid and blocking the storage area for people, the automatic crane comes into operation. It picks up loads automatically or manually from the storage area, the shuttles or the roller conveyors, lifts them and transports them to the fir tree storage area. A trolley travels on both girders of the crane and is equipped with a winch, a telescope and a slewing gear. Depending on the length, the automatic crane places the loads in the appropriate storage position in the finished parts warehouse.

Safe and space-saving accessibility

The crane can be controlled both manually via radio control and automatically: In automatic mode, the warehouse management system used by Kind & Co. gives the commands for the crane's movements, and all drives are then controlled automatically. Of course, the transport route with the automatic crane also works in reverse from the finished parts warehouse to the storage area. Erich Schäfer successfully mastered the challenge of ensuring that the automatic crane could be accessed safely and for servicing purposes, especially given the limited space available in the finished parts warehouse, by adopting a solution-oriented approach. “We considered all possible scenarios in order to have solutions ready, including the unlikely event that the automatic crane is defective and locked in the finished parts warehouse and is extremely difficult to access. The special feature of our solution for Kind & Co. is that the automatic crane can now be accessed safely in three different ways - even in the event of an accident. Qualified personnel can access both the crane bridge on one side via a safety gate and the trolley or crane head girder via a safety gate,” says Mr. Stephan Skelo, Project Manager at Erich Schäfer.